What We Do

Become a world-class EVA polymer material manufacturing company

Guangdong Xinfengjiang Technology Co., Ltd. is a large domestic manufacturer of EVA polymer materials, integrating R&D, design, production, and sales. The industrial park was built in 2007. Since its establishment, the company has continued to innovate through independent research and development and expand its scale. Now it has a factory area of approximately 11,000 square meters, with a number of high-salary technical developers and efficient and dedicated workshop employees...

Company Founded in

Number of Employees

Building Area

Annual Capacity (Ten Thousand Pieces)

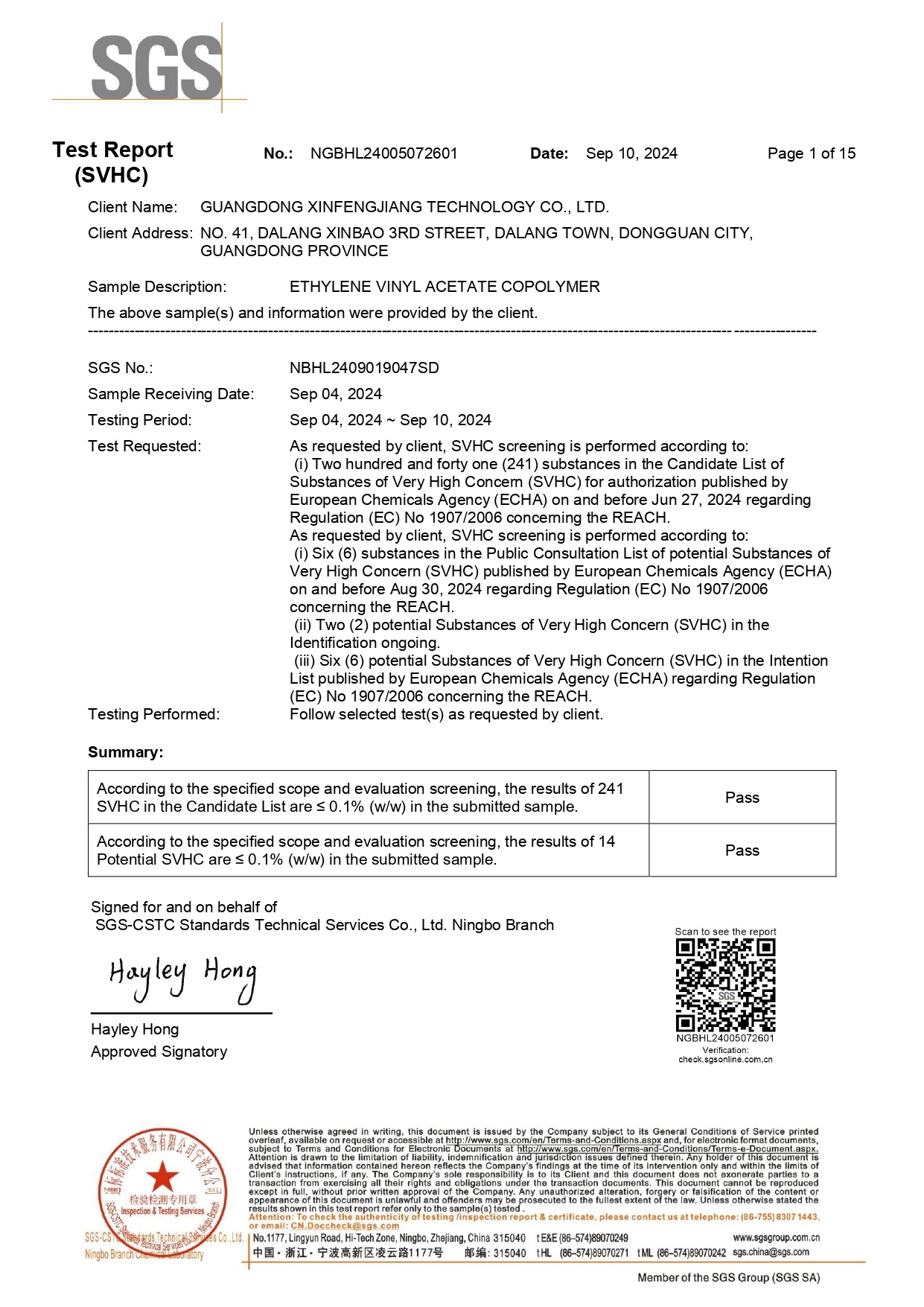

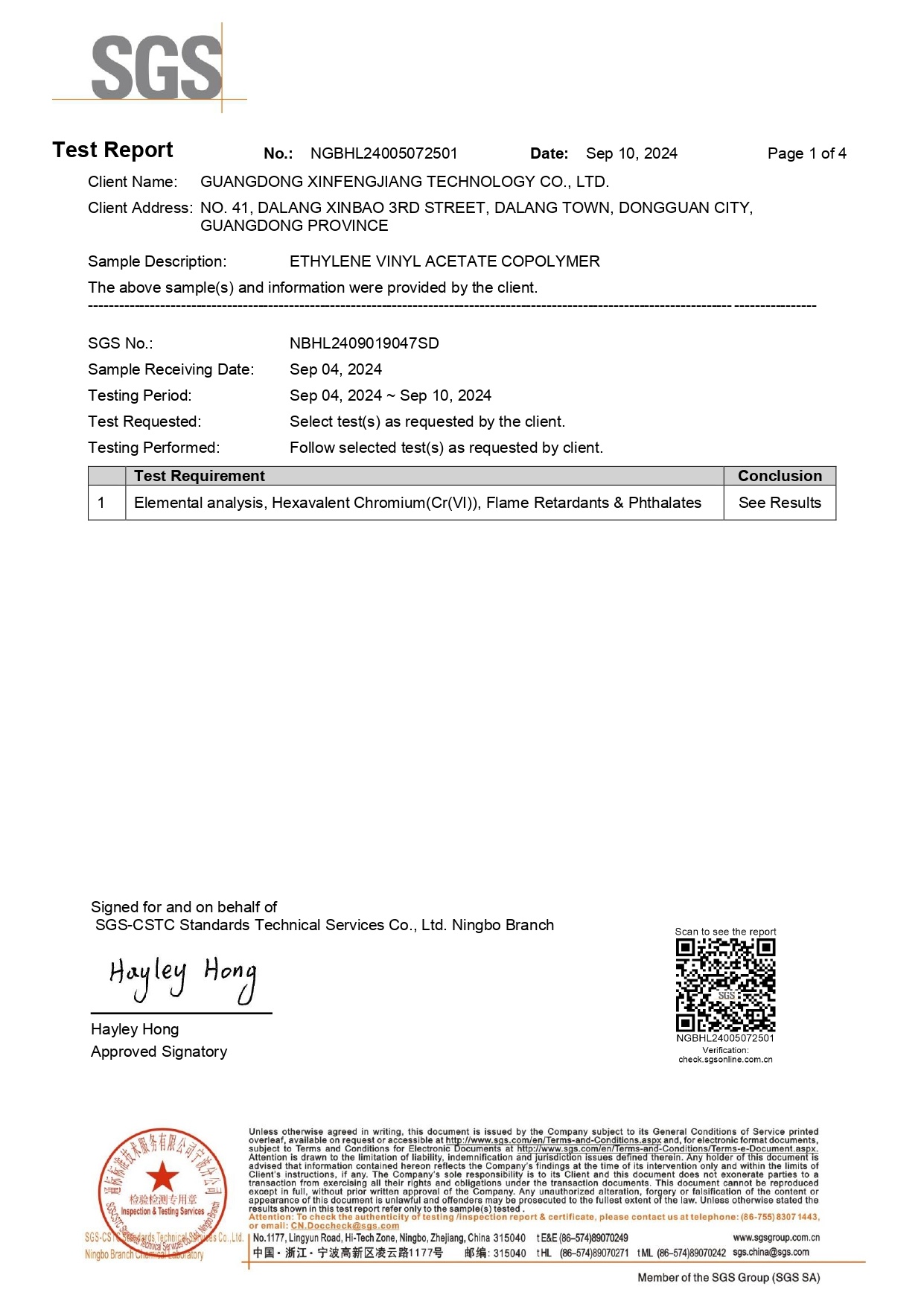

Certificate

Process

Excellent equipment to ensure product quality

We attach great importance to independent technological research and development and talent cultivation. We are equipped with a professional technical R&D center and have established a modern equipment production workshop to optimize the production process in real time.

knowledge

Discover the Versatility and Benefits of Silicone Beach Bags

09-25

2025

22

/09/2025

knowledge

The Ultimate Guide to Packing a Rubber Beach Bag for a Day Out

The Ultimate Guide to Packing a Rubber Beach Bag for a Day Out When planning a day out at the beach, ensuring you have the right items packed in your rubber beach bag can make all the difference. Whether you’re heading to the shore for a relaxing day in the sun, a family outing, or an adventurous beach day, knowing what to bring is crucial. This guide provides you with an exhaustive list of essent

19

/09/2025

knowledge

Discovering the Versatility of Bogg Bag for Softball Enthusiasts

When it comes to staying organized and stylish on the field, the Bogg Bag has emerged as a popular choice among softball enthusiasts. This innovative bag not only embodies functionality but also provides a unique aesthetic appeal that resonates with players of all ages. Let's delve into why the Bogg Bag is becoming a staple accessory for those passionate about softball. One of the standout feature

18

/09/2025

knowledge

OEM & ODM EVA Beach Bag Services from Our China Factory

When it comes to beach outings, having the right gear can make all the difference in your experience. One of the most essential items you need is a reliable beach bag, and the silicone beach bag has emerged as a popular choice among beach-goers. This guide explores the benefits, features, and considerations of silicone beach bags to help you make an informed decision. Silicone beach bags are craft

Our services

Xinfengjiang · Sincere service for you

If you are interested in our products or have other questions, please leave us a message